About Cooling Tower

The cooling tower is a device that utilizes water to transfer wasted heat to the air. The industrial cooling towers work by getting rid of heat from water through a small amount of water vaporization, which is then circulated through the device. The mixture of hot water with cooler air releases latent heat from vaporization, which causes the liquid to chill.

If you’re looking down from the top of a tower, you may see square units with fans on top of the lower buildings. They are cooling towers made of water.

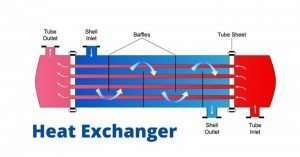

Cooling Tower parts

- Frame and casing: support exterior enclosures

- Fill: facilitate heat transfer by maximizing water / air contact

- Cold water basin: receives water at bottom of tower

- Drift eliminators: capture droplets in air stream

- Air inlet: entry point of air

- Louvers: equalize air flow into the fill and retain water within tower

- Nozzles: spray water to wet the fill

- Fans: deliver air flow in the tower

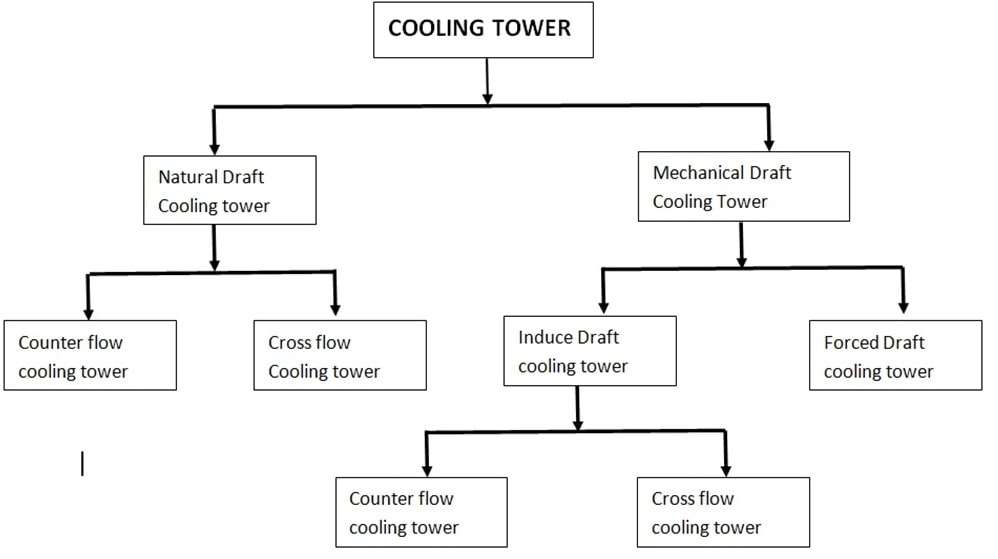

Cooling Tower Types

Cooling towers are typically essential for industrial processes. These high, open-topped cylindrical structures provide cooling water derived from HVAC or industrial comfortable cooling flow. They are classified based on the kind of draft (natural or mechanical) and the direction in which airflow flows (counter or cross).

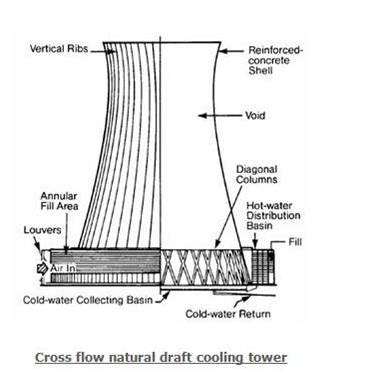

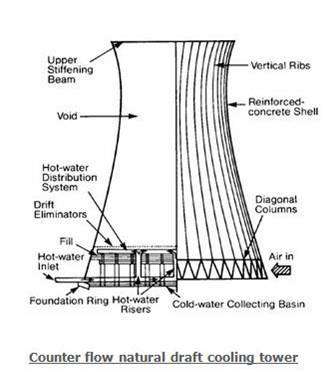

A. Cooling tower natural draft

The towers are high and are shaped in a hyperbolic way to allow for proper airflow. They have typically used in big power plants or industries with an unlimited cooling water flow.

Feature of Natural Draft Cooling Towers

- Hot air moves through tower

- Fresh cool air is drawn into the tower from bottom

- No fan required

- Concrete tower <200 m

- Used for large heat duties

B. Mechanical Draft Cooling Towers

Mechanical Draft Cooling Tower forces air into the building by an air compressor that circulates air around the tower. The most common fans that are used in these towers are propeller and centrifugal fan. While mechanical draft towers work better than natural draft towers, they use more energy and cost more to operate.

Feature of Mechanical Draft Cooling Towers

- Large fans to force air through circulated water

- Water falls over fill surfaces: maximum heat transfer

- Cooling rates depend on many parameters

- Large range of capacities

Mechanical Draft Cooling Towers are three types

- Forced draft Tower Systems

- Induced Draft Tower Systems

1. Forced Draft Cooling Tower Systems

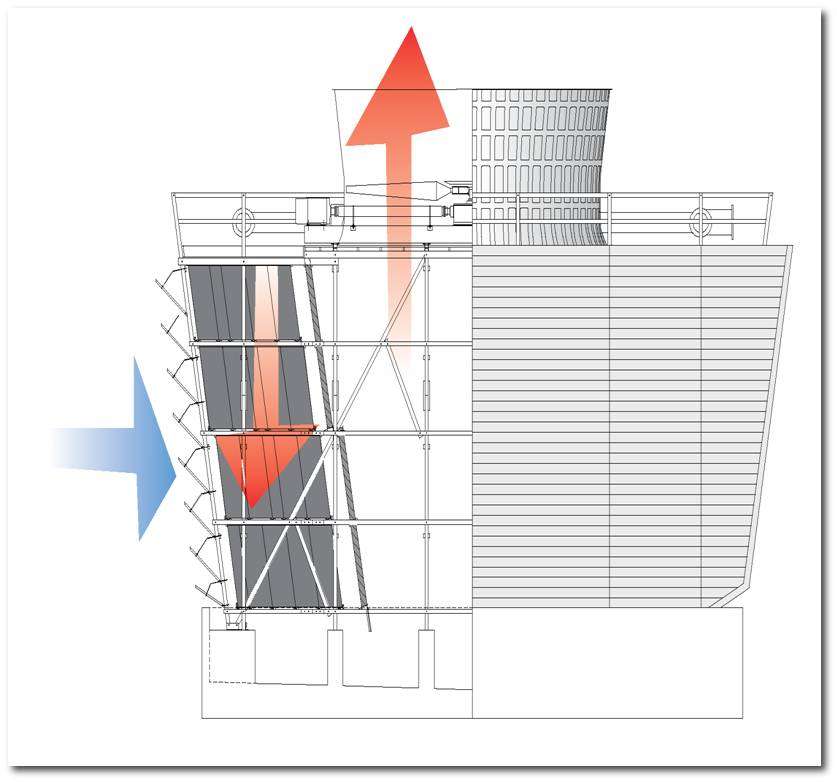

This cooling tower design is similar to an induced draft, but the main distinction is that the air-moving fan is situated in the tower’s middle, allowing air to flow through from below. The use of these cooling towers is restricted because of water distribution issues, high horsepower fans, and the potential for recirculation.

| Advantage | Disadvantage |

| Suited for high air resistance & fans are relatively quiet | Recirculation due to high air-entry and low air-exit velocities |

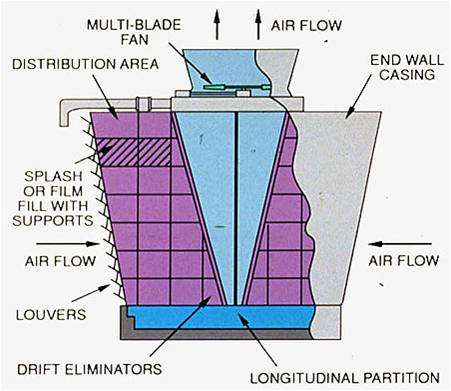

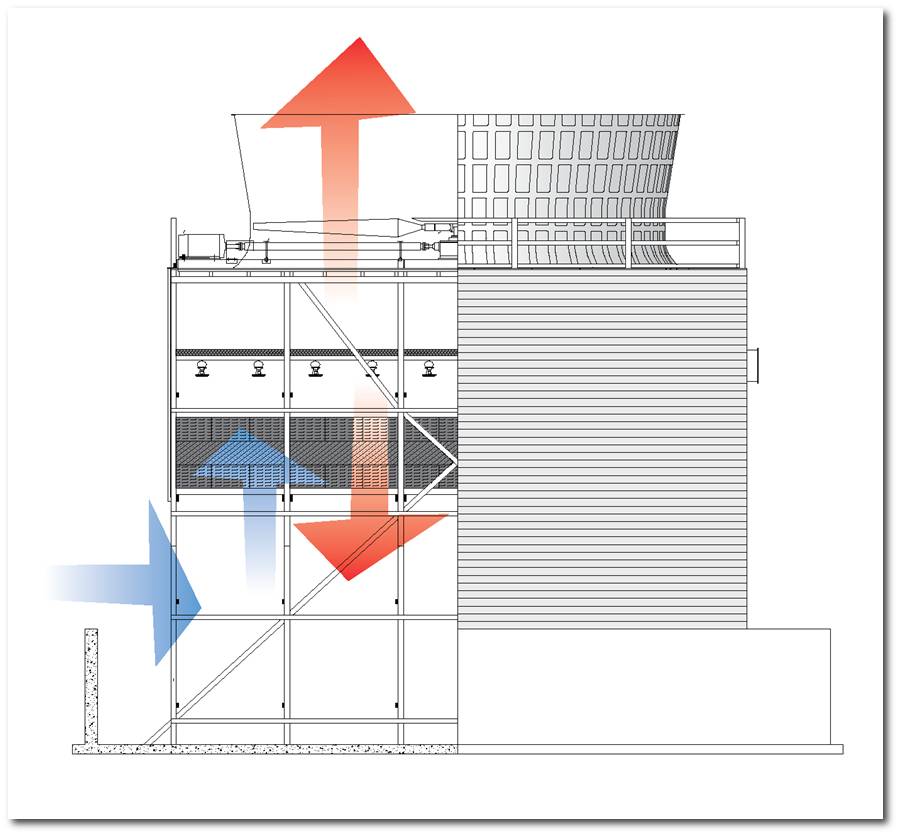

2. Cooling tower induced draft

Most of them are installed with a fan in the upper part of the cooling tower, which lets hot air out and circulates air around. The high velocity of air leaving the cooling tower minimizes the possibility of recirculation. To prevent the water droplets losses within the air, the Drift eliminators are employed in the cooling tower.

| Advantage | Disadvantage |

| Less recirculation than forced draft towers | Fans and motor drive mechanisms require weather-proof |

Induced Draft Tower Systems are two types

- Crossflow Cooling Tower Systems

- Counterflow Cooling Tower Systems

i) Crossflow Cooling Tower Systems

The design allows air to flow vertically across the fill and the tower’s structure, opening up into an open plenum. Hot water is pumped downwards from the distribution basins. But, motors and fans drive need weatherproofing to protect against moisture, resulting in freezing and making it less efficient.

In Cross flow, cooling towers use splash fill media through which the incoming cool air flows horizontally ACROSS the downward flow of hot water from the top distribution basins.

ii) Counterflow Cooling Tower Systems

The majority of Delta Cooling Towers have counterflow, which has these benefits. This Cooling Tower is designed to flow upwards, and the counter-current of hot water flows downwards for cooling the air. It ensures maximum performance from every plan area and reduces the need for pump heads. Additionally, the counterflow cooling tower will notice up during cold weather and reduce energy consumption over the long term.

In counter flow cooling towers, the incoming cool air moves vertically up through the fill media, COUNTER to the downward flow of hot water coming from the distribution laterals.

Types of Cooling Tower

Assessment of Cooling Towers

| Measured Parameters | Performance Parameters |

| 1. Wet bulb temperature of air | 1. Range |

| 2. Dry bulb temperature of air | 2. Approach |

| 3. Cooling tower inlet water temperature | 3. Effectiveness |

| 4. Cooling tower outlet water temperature | 4. Cooling capacity |

| 5. Exhaust air temperature | 5. Evaporation loss |

| 6. Water flow rate | 6. Cycles of concentration |

| 7. Air flow rate | 7. Blow down losses |

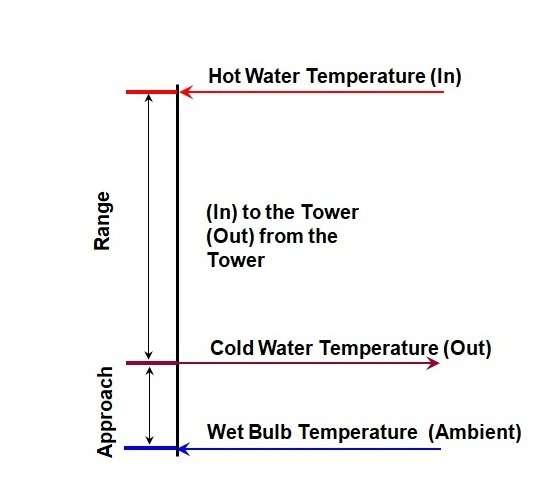

Cooling Tower Approach and range

1. Cooling tower range

Difference between cooling water inlet and outlet temperature:

Range (°C) = CW inlet temp – CW outlet temp

High range = good performance

2. Cooling Tower Approach

Difference between cooling tower outlet cold water temperature and ambient wet bulb temperature:

Approach (°C) = CW outlet temp – Wet bulb temp

Low approach = good performance

3. Cooling Tower Efficiency Formula

Effectiveness in % = Range / (Range + Approach)

= 100 x (CW temp – CW out temp) / (CW in temp – Wet bulb temp)

High effectiveness = good performance

4. Cooling Capacity

Heat rejected in kCal/hr or tons of refrigeration (TR) = mass flow rate of water X specific heat X temperature difference

High cooling capacity = good performance

5. Evaporation Loss

Water quantity (m3/hr) evaporated for cooling duty = theoretically, 1.8 m3 for every 10,000,000 kCal heat rejected

= 0.00085 x 1.8 x circulation rate (m3/hr) x (T1-T2)

T1-T2 = Temp. difference between inlet and outlet water

6. Cooling Tower coc

Ratio of dissolved solids in circulating water to the dissolved solids in make up water.

7. Cooling Tower blowdown

Depending on cycles of concentration and the evaporation losses

Blow Down = Evaporation Loss / (C.O.C. – 1)

8. Makeup

Makeup = Evaporation Loss + Blow down +Drift loss

Importance of Cooling Towers

Industrial cooling towers are the most important component of refrigeration systems. They are commonly found in industries like power plants, steel mills, chemical processing, and many manufacturing firms in which cooling for the process is required. Additionally, commercial cooling towers can comfort-cooling to big commercial structures like airports, schools, hospitals, or even hotels.

An industrial cooling tower could be more extensive than HVAC systems and is utilized to eliminate the heat absorbed by circulating cooling systems used in refineries, power plants and petrochemical plants and natural gas processing plants, as well as food processing plants and various other industrial establishments.

The equipment and processes of industries that produce huge amounts of heat have to be continuously cooled to keep running effectively. One of the most effective, efficient and cost-effective methods of removing heat is to put it in cooling towers.